WhatsApp)

WhatsApp)

Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation using Discrete Element Method (DEM). The results carried out by both ...

Grinding in Ball Mills: Modeling and Process Control ... a ball milling device usually consists of a ... The speed of rotation of the mill determines three basic ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Milling can be done either wet or dry, ... The theoretical critical speed of a ball mill is the speed at which the centrifugal force is

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

End Mill Training Speed and Feed Calculations. ... With CNC milling, ... The spindle speed rate of the cutter.

Martin Chick Associates CNC Programming ... Home. Resources. Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code ...

China Ball Milling Select 2017 high quality Ball Milling products varied in Motor Type, Motor Power and Rotationl Speed from certified Chinese Milling factory, China Balls ...

Ball Nose milling application information. Feed, speed and diameter compensation. Recommended ball nose cutting speeds. Troubleshooting.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Ball Milling Ball Speed Wet ballmilling route is employed to prepare sulfurcarbon nanotubes composites The influences of solvents, ...

CNC Machinist High Speed Machining (HSM) Speed and Feed Calculator For Milling, Drilling and Turning

The takeoff speed (v) of the milling ball at the position P1 (x1, y1) reads v = √ Ω2r2 d +(Ω ω)2r2 v +2Ω(Ω ω)rvrd cosϕ1. (12) The position vectors for the takeoff and P1 (, ...

Synthesis of Nanomaterials by High Energy Ball Milling W. Cao . Skyspring Nanomaterials, Inc. ... Hence, the planetary ball mill can be used for highspeed milling.

Surfactantassisted ball milling: a novel route to novel materials with controlled nanostructure... 5 below this critical speed to keep the ball moving.

Hence, the planetary ball mill can be used for highspeed milling. Get Price. Retsch : Products : Milling : Planety Ball Mills

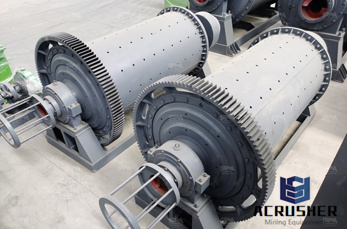

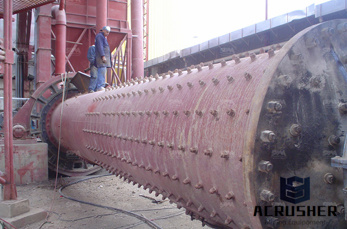

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

High Speed Ball Nose End Milling of Inconel718 E.G. Ngl, D. W. Lee2, A. R. C. Sharmanl, R. C. Dewes'', D. K. Aspinwal13 ''School of Manufacturing and Mechanical ...

Pressure and speed should be regulated and checked ... Ball mill technology is one of the most commonly preferred types of machinery in the mining and milling ...

Amazing deals on this 2 Speed Benchtop Milling/Drilling Machine at Harbor Freight. Quality tools low prices.

Feeds Speeds For Milling Cutters. The proper selection of feeds and speeds is the most important factor in the economical application of any cutting tool.

Critical Rotation Speed for BallMilling on ResearchGate, the professional network for scientists.

Speed Feed Calculators and Common Formulas Speed Feed Calculators. Dapra''s Speed and Feed calculators will automatically provide the necessary speed and feed for ...

Bigger size media has more crushing effect as well as smaller sizes better grinding effect. Rotation speed of the ball mill is also one of the factors changing thenbsp

WhatsApp)

WhatsApp)