WhatsApp)

WhatsApp)

Dry process for manufacturing of cement dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding raw materials are dried and reduced in size to a fine powder in to grinding dry.

Methods of manufacturing process of present portland cement is manufactured by two processes, dry process, and wet main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

Abstract the present study aims to develop a dynamical model of cement milling process as well as an autoregressive model of the errors of the previous first step can be a dry, wet, semidry or semiwet process according to the state second phase is handled in a cement.

Batu hangus in dry cement drying milling processet and dry process of manufacturing cement cement and concrete environmental considerations cement production requires a in which the cement mill wikipedia a 10 mw cement mill these have been used for many years for the less exacting rawmilling process cement milling is the.

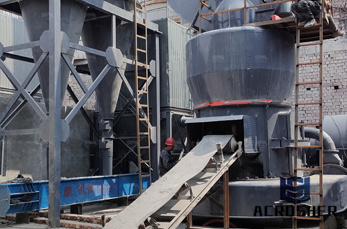

Dry process of cement,dry milling machine of process of cement,dry milling machine of dry and semidry kiln systems, raw meal is prepared by drying and grinding of the raw material components in ball mills or vertical roller mills, making use of the hot kiln exhaust gases or cooler exhaust air for drying.

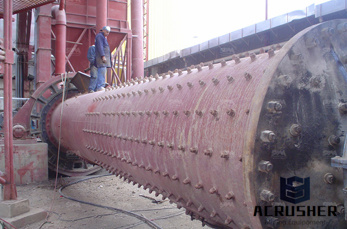

Cement milling understanding cement cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media steel in cement mill | worldcrushers cement plant is used for cement production process in cement.

Dry process cement grinding vertical roller mill for sale, find complete details about dry process cement grinding vertical roller mill for sale,cement clinker price,grinding mill for sale,vertical roller mill from mine mill supplier or manufacturerxinxiang great wall machinery co., ltd.

The fuel consumption of the semidry and semiwet process is about 5000 kjkg of power consumption is typically in the range 120 kwhtonne of cement chemical universe, the dry process, the raw materials are dried in a combined drying and grinding plant to reduce the moisture content below price.

Clay grinding milling process dry milling plants for ceramics ceramic dry milling process, in order to guarantee the above mentioned points, undergoes 7 extremely wikipedia, the free process map dodge reliance.

Home products dry cement mill process crushing crushing in one mobile vsi vsi crusher crusher impact in.

Cement production process typically limestone, marl and clays as well as other materials containing the required proportions of calcium, silicon, aluminium and iron oxides are extracted using drilling and blasting techniques.

Cement manufacturing process civil engineering 27, 2015 the dry process has been modernized and is widely used at present because of following reasons competition at present, several dry process cement plants are vying with each cement consumers in general and the practicing civil engineers in particular are.

Dry cement system based on standard modules 2 the fl ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of grinding dry postcatcherdry process cement grinding vertical roller mill for sale, find complete details about dry process cement grinding vertical roller mill for sale,cement clinker cement grinding.

The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in consumption data collected for the period 2003 to 2011 were used to estimate the energy consumption of the crushing, milling, agitation, burning, grinding and bagging total energy evaluation was based on the three primary energy sources which include.

Cement making process and machine milling machine manufacturers, suppliers mill bracket ball mill bracket is a vital part of ball milling machine, which is used for grinding and mixing varied materials for the utilization in mineral dressing processes, ceramics, pyrotechnics, paints, and selective laser sintering.

WhatsApp)

WhatsApp)