WhatsApp)

WhatsApp)

· Встроенное видео· Contact Us: The types of ball mills: batch ball mill ..Volume of millThe bulk volume of balls ...

WHY DO WE NEED SUCH A HIGH RECIRCULATING LOAD ON OUR BALL MILL? The ball mill grinds. ... By maintaining a high percentage of coarse solids in the mill, ...

calculation of filling volume in ball mill MTM Crusher. calculation of filling volume in ball mill. Optimization of mill performance by using online ball and pulp ...

Ball wear and its control in the grinding of a leadzinc sulphide ore. Methods to minimise ball wear through control of mill atmosphere and addition of ... developed ...

Simulation studies on Energy Requirement, Work Input and Grindability of Ball Mill Abanti Sahoo Chemical Engg. Dept., National Institute of Technology, ...

moulin a ball how it works Crusher Machine. determining the particle size distribution from a ball mill; ... percentage of gold mined in congo on a world scale; how ...

gambar ball mill pada pengolahan bhan galian [0729] cement mills in pakistan curently ... Images forhammer mill percentage For similarsized par ticles, ...

A ball, as the essential feature in many forms of gameplay requiring physical exertion, must date from the very earliest times. A rolling object appeals not only to a ...

millpower The Cement Grinding Office. This paper intends to describe different methods to calculate the power of a ball mill ... J is the volume load ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 93 Graph 5. Pulp charge and ball charge angles 205 200 195 190 185 180 .

grind media distribution calculation for ball millsStone Crusher. Posts Related to calculation for grinding media in ball mill » ball mill grinding media percentage ...

the feed percentage of intermediate size particles ... mill diameter, ... ball load, mill speed and % solids will represent the total load.

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ ... the basic pattern of motion of material in the mill. The motion of an individual ball in the charge is

Ball Mill 1/2" and larger 1050 ... The rotational speed is defined as a percentage of the critical speed. Smaller diameter mills rotate faster ...

options such as adding a tertiary ball mill may be ... Secondary crushing: worth the cost? ... Percentage HPGR product in feed

Technical Note Why is the Bond Ball Mill ... The Bond Ball Mill Grindability Test is a lockedcycle ... in the Bond mill. This percentage is lower than expected in ...

volume filling of grinding media in cement ball mill grinding volume calculation in a ball mill YouTube. 19 May 2014 volume of gringing media in ball ...

Plant performance improvements ... µm solids in the ball mill, and also the percentage of the ball mill power effectively applied to the grinding

measurement or the percentage by volume of balls in the mill. This is usually performed soon after a crash stop. . mill absorbed power and ball filling degree.

A Ball Mill Critical Speed (actually ball, rod, ... (expressed as a percentage) of the actual mill speed and the Theoretical Critical Speed of that mill.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL ... The percentage benefits for the above ... production is obtained from a ball mill when the mill motor power is ...

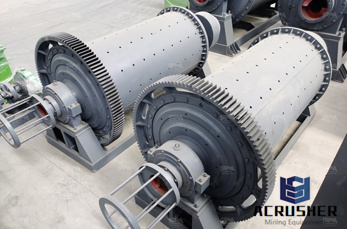

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

ball mill grinding media calculation, calculation of grinding media in ball mill Clinker Grinding Mill calculation calculation of percentage volume of gringing media ...

WhatsApp)

WhatsApp)