WhatsApp)

WhatsApp)

How Cement is made at Continental. Cement is made from common materials such as limestone, clay, silica, and iron ore. Principle raw materials are a blend of 88% ...

Ordinary Portland Cement is prepared by a fullyautomated, dry manufacturing process using state of the art technology under strict quality assurance at all stages of ...

Composition of cement. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration.

Gypsum plaster Gypsum plaster is what the average person on the street thinks of when plastering is mentioned. This generally connotes an image of an old house with ...

Gypsum is a mineral and is hydrated calcium sulfate in chemical form. Gypsum plays a very important role in controlling the rate of hardening of the cement.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the ...

PRODUCTS. What Does Your Job Demand? Since 1972 PABCO® Gypsum has been manufacturing quality gypsum products for your needs. Select a feature to find the .

Mar 29, 2012· Lucky Cement Limited (LCL) is Pakistan''s largest producer and leading exporter of quality cement with the production capacity of tons per annum

Alternative Fuel Use in Cement Manufacturing Implications, opportunities and barriers in Ontario White paper for Workshop on Alternative Fuels in Cement Kilns

gyp·sum (jĭp′səm) n. A widespread colorless, white, or yellowish mineral, CaSO4·2H2O, used in the manufacture of plaster of Paris, various plaster products, and ...

In general, the early strength of portland cement concrete is higher with increased percentages of C

Cement and Lime. Cement is a crucial commodity in a developing country like South Africa, both for domestic and industrial construction. The industry is forecasting ...

Division 09 Fire Resistance and Sound Control Design Manual CertainTeed Gypsum Board Systems Manual

American Gypsum has been manufacturing, selling, and distributing gypsum wallboard products throughout the United States for over 50 years.

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Aims to improve cement and concrete and its uses, and raise the quality of construction. Page includes industry news magazine.

Nov 15, 2007· Cement making process. I don''t owe any copyrights for this video. I just uploaded it because there was no good video about cement making process at that time.

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 4 WORLD BANK GROUP • Developing a staged combustion process .

Introduction Introduction Introduction The Lafarge Gypsum business unit (''Gypsum''), part of Lafarge South Africa, manufactures and markets gypsumbased building ...

I. GYPSUM BOARD CONSTRUCTION WHAT IS GYPSUM BOARD? Gypsum board is the generic name for a family of panel products that consist of a noncombustible core, .

Executive Summary Cement, Lime and Magnesium Oxide Manufacturing Industries i EXECUTIVE SUMMARY OF THE REFERENCE DOCUMENT ON BEST AVAILABLE TECHNIQUES IN THE CEMENT ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

We manufacture the most extensive line of architectural casting products available, including GRG (Glass Fiber Reinforced Gypsum), GFRC (Glass Fiber Reinforced ...

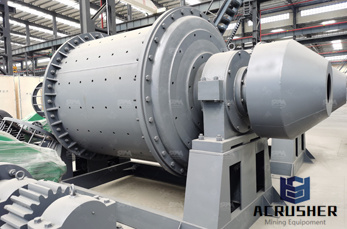

Megatech Supplier of mini cement plants, industrial mini cement plants, cement making machines, industrial cement plants, vertical shaft kiln machine, industrial ...

WhatsApp)

WhatsApp)