WhatsApp)

WhatsApp)

202055Urea SNCR Systems NO X OUT and HERT NO X OUT SNCR Process. The NO X OUT SNCR Process is a ureabased Selective NonCatalytic Reduction SNCR process for reduction of oxides of nitrogen NO X from stationary combustion process requires precisely engineered injection of stabilied urea liquor into combustion flue gas temperatures as high as 2500 F

Cement Price Per TonCement Prices In PakistanPorcelain Granule Rotary Kiln Find Complete Details about Cement Price Per TonCement Prices In PakistanPorcelain Granule Rotary KilnRotary Kiln IncineratorPorcelain Granule Rotary KilnRotary Kilns from Cement Making Machinery Supplier or ManufacturerLuoyang Zhongde Heavy Industries Co. Ltd

Having run out of timber for fuel the European cement industry switched to coal and coke a form of cooked coal. Bottletype kilns which were slow and wasted heat gave way first to shaft kilns and eventually to rotary kilns which can run for a year or longer before being shut down for maintenance

Oxbow is a worldwide supplier of numerous industrial materials each critical to the production of a variety of products. From production and sourcing to handling and logistics to technical support Oxbow plays an important role in the manufacture of such critical materials as aluminum steel glass wallboard and cement

The cement manufacturing industry has been a major consumer of the fuelgrade Petcoke. Global demand for cement remains strong as countries such as China India Brail and Mexico witness rapid urbaniation and industrialiation which is reflecting favourably on the Global Petroleum Coke

cement sector1 earlier this year new information has come to light which supports Sandbags findings. It reveals that EU cement producers have not experienced loss of competitiveness and have very little risk of experiencing carbon leakage. This is covered in more detail below. CARBON PRICING

Effects from carbon pricing and antileakage policies in selected industrial sectors in Spain Cement Steel and Oil refining iron is made up of sinter and pellets both are products from iron ore and coke from coal. All these elements are put together into a blast furnace to make pig iron. dry cement kilns 5 semidry ones and 5

202052Pricing . Imported petcoke prices in India rise on tight supply The March quarter is a seasonally strong one for cement producers but cement prices are plunging across the country which is hurting margins. After the ban cement producers were exempted and allowed to use petcoke at their kilns but the Court then imposed a hike on the

als in coke depend directly on the origin of the crude oil from which it comes and the amounts present determine the use to which it is put. Highsulphur coke which is less valuable is used primarily for fuel in utility boilers and cement kilns. Most lowsulphur cokeabout 40 percent of all green cokeis cal cined

In the most general sense of the word cement is a binder a substance which sets and hardens independently and can bind other materials together. The name cement goes back to the Romans who used the term opus caementitium to describe masonry which resembled concrete and was made from crushed rock with burnt lime as binder

A number of cement kilns have already made the switch from natural gas to coal and currently 87 percent of cement kilns in the United States use coal as the primary When natural gas with no nitrogen in the fuel is used in the burning one of a cement kiln the NOX emissions are significantly higher than when coal is used

Coal sampling and analysis standards 4 Abstract Each year billions of tonnes of coal are traded in regional and international market for use in power generation steel and cement making and many other purposes. In commercial operations the price of coal not only

The volatility of international prices of coal currency swings variations in shipping costs and dynamic pricing of petroleum coke all contribute to making it a big challenge to optimise the fuel basket for a cement plant. And it is no less intriguing to analyse and report on such a vibrant topic of the cement

Read more about Cement Coal Indias price rise to hurt big players on Business Standard. Power is not the only sector to fall prey to soaring coal prices. Several large cement producers are likely to be hit with Coal India announcing an increase in prices of coal effective 27 February. On an average coal prices will move up by 12 per

Cement is a finely milled mineral powder usually grey in colour The most important raw materials for the production of cement are limestone clay and marl Mixed with water cement serves as an adhesive to bind sand gravel and hard rock in concrete Cement hardens both in the air and under water and remains in its hardened state once reached

Energy options for heavy industries under Canadas carbon pricing policy. The steel industry requires coal or petroleum coke pet coke as a carbon source for steel manufacturing. The stone wool insulation manufacturing requires the heat intensity of coal to melt rock. Tires are currently used in cement kilns in the United States. In

202014Cement Bonding Or What August 18 2008. and this can only put pressure on the companies pricing of their product. the price of energy. Not only is making cement in kilns extremely

Indian cement makers are increasingly turning to the thermal coal market following a rally in petroleum coke import and domestic prices. NEWS ANALYSIS. Indian cement switch to coal from petcoke. pricing updates and webinars simply leave your details below

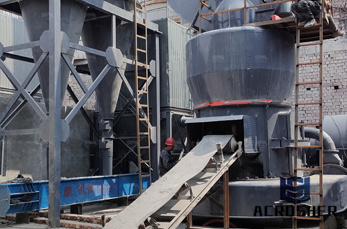

Kilns and mills. An integrated cement plant has a kiln fuel deposits storage silos for blended raw materials and clinker and a mill to grind the clinker into cement. A standalone mill only requires the clinker storage silos and the mill. Nine integrated cement plants and three standalone mills operate in Central America in 1999

202053Blanket ban on petcoke not a wise move. N Madhavan Pet coke ban to render 25 lakh workers in NCR jobless Assocham use of petcoke in cement kilns helps us to use our natural resources more

The global petroleum coke market is anticipated to witness a substantial CAGR during the forecast period of 2014 to 2020 says the report by Transparency Market Research. As per the report the growth of the market is attributed to growing application in cement industry. Moreover to it is widespread application in various businesses the global petroleum coke market is projected to

As alluded to earlier fuel for the kiln coal or coke. And later oil and later yet natural gas. Cement kilns run hot so were a favorite place to incinerate other items such as tires since the heat of the kiln consumed the visible smoke

GITCO has emerged as an eminent leader in fuel grade petcoke sourcing and sales handling more than a million tons per year. Fuel grade petcoke is typically very high in heating value produces virtually no ash when burned and is most commonly used in electric power plants and cement kilns

Louisville Already approved to burn scrap tires as fuel in addition to coal and petroleum coke CEMEX Kosmos now wants to blend in scrap plastic and wood to the fuel that fires its superhot cement kiln in southwest Louisville according to public officials

WhatsApp)

WhatsApp)