WhatsApp)

WhatsApp)

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling ... process Tip of

Ball mill is an efficient tool for grinding many materials intofine powder. The Ball Mill is used to grind many kinds of mine andother materials, or.

[ P171Dec 3, 17:3019:30 ] Enhancing mechanical property of platinum alloy by ball milling process. Plasticity of nanocrystalline alloys with chemical order: on

Ball mill is an efficient tool for grinding many materials intofine powder. The Ball Mill is used to grind many kinds of mine andother materials, or.

The tumbler ball mill is a cylindrical container rotated about its axis in which balls impact upon the powder charge. The balls may roll down the surface of the ...

Milling is a cutting process that uses a milling cutter to remove material from the surface of a workpiece. The milling cutter is a rotary cutting tool, often with ...

How to Use a Ball Mill Safely and Effectively ... ball milling is the best way for the amateur fireworker to reduce particle size in their chemicals.

Effect of planetary ball milling process parameters on the nitrogen adsorption properties of multiwall carbon nanotubes Ibolya Zita Papp • Ga´bor Kozma • Ro ...

what is ball milling process. Ball Mill Grinder Machine, Grinding and Milling FAB 3R. A ball mill can also be helpful in the process of cold welding, and produces ...

application of taguchi''s method on the purifying . ball milling process were duration of milling, jar volume and ball per powder Keywords: ball milling, taguchi''s ...

October 2001 Materials Letters 51 2001 139–143Ž. rr Fabrication of aluminum flake powder from foil scrap by a wet ball milling process Hong), Kim

High Energy Ball Milling Process – Find Ball Mill Supplies . Sm–Co Hard Magnetic Nanoparticles Prepared By Surfactant .The powders were ground inamillingvial ...

The high energy ball milling (HEM) process features a strong mechanical energy transfer into processed materials. Thereby the production of pseudo alloys, ...

Ball Milling method for synthesis of nanomaterials. ... Steps in ball milling method; 1. ... This process of ball milling is done approximately 100 to 150 hrs to get ...

The most innovative milling technology on the market today offers greater throughput and product size ... the ball milling process is long and tedious, ...

The milling process can modulate the relative portion of antisite defects and vacancies in crystal, and the Bi2 ... (Se,Te) 3 crystal after ball milling process.

Grinding in Ball Mills: Modeling and Process Control ... the milling process takes place during rotation as a ... The design of a ball mill can vary significantly ...

View Ball Mills presentations online, ... BALL MILLS PowerPoint PPT Presentations. ... During the milling process, ...

Manufacturing of aluminum flake powder from foil scrap by dry ball milling process SeongHyeon Hong*, DongWon Lee, ByoungKee Kim Department of Materials ...

A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix metals or raw materials for further processing. Various materials are placed into the mill drum and rotated with the mined materials that are to be crushed.

10 items· Great but Cheap Ball Milling Process, Cheap Jewelry,Lights amp; Lighting,Automobiles amp; Motorcycles,Home amp; Garden, as well as Cheap and .

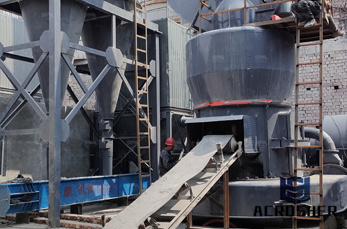

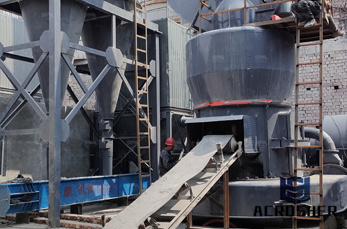

Ball Milling Process Introduction: The ball mill is the key milling machine to break and to smash materials. It also is an effective tool for many materials ground ...

Recently, ball milling process is performed in differ ... Surfactantassisted ball milling: a novel route to novel materials with controlled nanostructure ...

Theory and Practice for . Jar, Ball and Pebble Milling . Types of Mills . ... Fundamentally, milling is a process for reducing the particle size of solids

WhatsApp)

WhatsApp)