WhatsApp)

WhatsApp)

500 TPD cement plant include the steps of crushing, cement raw Material preparation and homogenization, preheating and decomposition, clinker calcination, cement grinding and cement packing. The design of 500 tpd new dry ...

Capital Market Day 2009 22 Proposal stage and signing of contract Optimal process and Advanced process designAdvanced process design low production cost Optimal process and low production cost FLSmidth has in house ...

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 C) in a cement kiln; grinding ...

Cement Plant Operations Handbook 5th Edition 17 SAMPLE 15. Cement Plant Assessment Data List 195 1. General – 2. Administration and Commercial – 3. Quarry – 4. Drying – 5. Raw Milling – 6. Blending – 7. Kiln – 8. Fuel – 9.

Material Mix Control Mining + in Cement Plant Automation Swain Crushing Grinding Finished Grinding G,, b Product + Burning + T he objective of this article is the development of a novel raw material mix proportion ...

Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement ...

24 Fasil Alemayehu et al.: Minimization of variation in clinker quality to raw mix control and the homogenization process. To ensure a constant quality of the product and maintain stable and continuous operation of the kiln ...

design of clinker / cement plant process (14 Jun 2012) Gulin supply Mining and construction equipment for mineral handling. The crushing, screening, washing, grinding equipment in stationary, portable, tracked type is available. Also ...

Boldrocchi Applications in Cement Plants HEAVY DUTY FANS Boldrocchi is the right partner to design, supply and successfully start up the complete gas handling and dedusting system of any cement plant. Boldrocchi has the ...

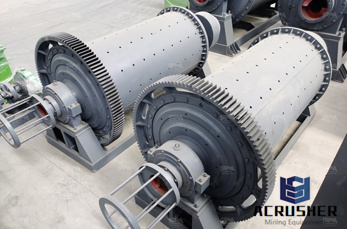

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

2 The cement production process Cement Production Cement production (Fig. 1) involves the fusing together of precisely controlled blend of calcium, silicon, aluminum, iron and small amounts of other ingredients at high ...

Cement Industry Cement Industry Siemens Read more in the new MineralsFocus magazine for the cement industry. tons of clinker per day, the Cong Thanh Cement Plant is cement clinker at ... » Learn More Manufacturing the ...

Owned by ACC, the plant''s operation and maintenance has been contracted to FLSmidth. This is one of the most successful cement plants operated by FLSmidth ... In the manufacture of Portland cement, clinker is the solid material ...

In the dry process cement plant, cooling of clinker takes place in cooler and hence length of the cooling zone is kept small in the kiln. For the current modelling, a constant wall temperature of 1400 C has been considered for the ...

Conveying and Storing in the Cement Industry 2 Contents 4 AUMUND Group Equipment in the Cement Industry 6 Clinker Transport 10 Conveying of raw meal, cement and additives 12 Transport of raw material, clinker, ...

Cementing Relationships ABB improves production process at Podilsky Cement plant Reprint from World Cement, March 2012 "We were delighted to renew the partnership with ABB for the installation of integrated electrical, control ...

Energy consumption for cement production As figure 1 shows, the thermal energy in exhaust gas from kilns and coolers is put to various uses including pre ... Figure 1 : Schematic diagram of the cement production process

5 Kiln cooler application Control challenges Controlling a cement kiln has always been a challenging task forand inconsistent clinker quality. cement plant operators. These days, a computerbased pyro control system is not merely nice to have, it ...

CEMENT INDUSTRY Output of a Seminar on Energy Conservation in Cement Industry Sponsored by United Nations Industrial Development Organization (UNIDO) and Ministry of International Trade and Industry (MITI), Japan Hosted ...

Process Control and Optimization in Clinker Making the Industrial ... Optimization of the clinker making process is usually done to reduce the heat ... Kiln burner management: the basic designs such as the fuel discharge angle of ...

Since meal enters the kiln at about 900 C, (compared with about 20 C in the wet process), the kiln can be shorter and of smaller diameter for the same output. This reduces the capital costs of a new cement plant. A dry process kiln ...

Application : Cement Plant Thermal Power Plant Annual Output : 150,000750,000 tons Process Type : New Dry Process Blaine Fineness : cm²/g Cement production line is the production line ...

VRRK: Latest Technology in Mini Cement Plant : Capacity ( 30 TPD TO 300 TPD ) Raw Materials : (purity not less than 88% Total Carbonate) ( Black Soil ) should be buttery Breeze / Petro Coke

With the goal of becoming one of the leading cement plants in the country, LS Cement Plant makes great efforts to become the leading economy of Vietnam, with its prestige and position in the world. The plant will successfully build ...

WhatsApp)

WhatsApp)