WhatsApp)

WhatsApp)

SAG Mill Process Control What do you prefer? Controlling Weight (within a range) by manipulating mill speed and keeping a constant feed rate?

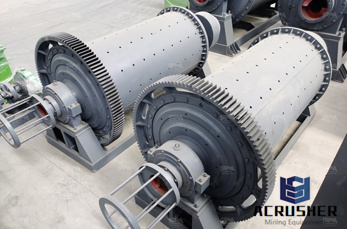

Ball mill, an energysaving grinding device, is widely used in mineral processing, building materials and chemical industries. Ball Mill grinds material by rotating a ...

Why use advanced process control? 2 Advanced process control from FLSmidth ensures that cement plants perform better, resulting in increased stability and higher

also be introduced to the mill during the grinding process to ... Attritor is better temperature control, ... The theoretical critical speed of a ball mill is the ...

Ball mills are the main machines in the grinding process. ... and test the overflow ball mill? (1) ... of Even Feeding to Ball M; Design and cost control of Xinhai ...

Model Predictive Control for SAG and Ball Mill Control ... additional degrees of freedom in adjusting to mill condition, while keeping the process stable.

Malawi crusher The cement mill. Malawi supplier of Brief description of a cement mill. usually ground using a ball mill. not the best way to get a clear picture of a ...

process, therefore in the ... the ball mill itself, the elevator lifting the ... Vol. XIX Automation and Control in Cement Industries Keviczky L. ...

Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while ...

J Control Theory Appl 2013 11 (3) 454–462 DOI /s Intelligent optimal control system for ball mill grinding process Dayong ZHAO 1†, Tianyou ...

Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while ...

Ball Milling Process Introduction: The ball mill is the key milling machine to break and to smash materials. It also is an effective tool for many materials ground ...

process control ball mill. Jaw Crusher. Jaw Crusher Product Introduction Xinhai jaw crusher with high ... The DMQX bead mill from Union Process provides highly ...

This paper shows a strategy for the fuzzy logic control system using an offline simulated ball mill grinding approach. In this study, a step change in the

Ball mill grinding circuits are essentially multivariable systems with high interaction among process variables. Traditionally grinding circuits are controlled by ...

Ball mill working principle,Ball Mill for beneficiation ... Ball mill working principle. Material from the feed device into the mill warehouse, there are ladder liner ...

Constrained model predictive control in ball mill grinding process on ResearchGate, the professional network for scientists.

1. Introduction. Ball mill grinding is a fundamental operation process, and in many respects the most important unit operation in a mineral processing plant.

Automatic Control System Design for Ball Mill in . This paper introduces the feed and density control scheme for the typical ball mill in concentration process.

NEUROCONTROL OF A BALL MILL GRINDING CIRCUIT USING EVOLUTIONARY REINFORCEMENT LEARNING A. v. E. Conradie and C. Aldrich* Department of .

Synthesis of Nanomaterials by High Energy Ball ... It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision ...

Previously, we used various process control agents (PCAs) to solve ... mill and experiment 0C was carried out in the planetary mill (ballto powder ratio of 25:1).

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

Abstract. ball mill grinding circuit is a nonlinear process characterised by significant process interaction, as a typical manipulated variable interacts with ...

WhatsApp)

WhatsApp)