WhatsApp)

WhatsApp)

ecoATCA Evaporative Condenser. The ecoATCA line of evaporative condensers represents Evapco''s commitment to product development. The line is comprised of .

working principle of ball mill pdf working principle of ball mill pdf,Ball mill WikipediaA ball mill is a type of grinder used to grind and blend materials for use ...

Ball Mills are primarily used for fine grinding. Ball Mill is key equipment which repulverises the material after it is crushed. Ball Mill is widely used in powder ...

Glass bottle crushed mach: Glass bottle crushed machine, glass recycled machine, glass hammer crusher for sale Working Principle

Working. In case of continuously operated ball mill, the material to be ground is fed from the left through a 60° cone and the product is discharged through a 30 ...

Manufacturer of Granulator Machine Ball Type Granulator Machine, Roller Type Granulator Machine, Disc Type Granulator Machine and Fertilizer Granulator Machine ...

In a DC motor, an armature rotates inside a magnetic field. Basic working principle of DC motor is based on the fact that whenever a current carrying conductor. is ...

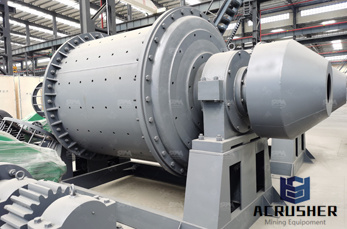

Working principle of Ball Mill This ball mill is a horizontal type cylinder rotating equipment which adopts outer gear transmission. This machine mainly consists of ...

BASIC PARTS, CONSTRUCTION, PRINCIPLE AND WORKING OF BALL MILL Basic parts. The basic parts involved in the ball mill are as follows: The metallic cylinder which .

Joyal Threering Micro Powder Mill,Threering Micro Powder Mill which manufactured by Shanghai Joyal Machinery is quite popular and easy to operate,if you .

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle ...

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Elliptifin® Cooling Coil. The new ecoATWBH Closed Circuit Cooler utilizes Evapco''s patented Elliptifin® coil design which assures even greater operating efficiency.

All kinds of ball mill in mining industry are the trend of bigness, mining scale, low grade deposit to reduce the basic investment and production cost requirements ...

From homogenizers to micropulverizers and media mills to jet mills, Federal Equipment Company carries a large variety of used mill equipment. All of the mill ...

The grinding effects of ball mill mainly rely on the impact and grinding of body to materials. The motion of ball mill body inside the mill tube contains several ...

shearing and impact results in size reduction as well as good dispersion. The principle of Attritor dry grind processing is achieved by an expanded moving bed of media.

BASIC PARTS, CONSTRUCTION, PRINCIPLE AND WORKING OF BALL MILL Basic parts. The basic parts involved in the ball mill are as follows: The metallic cylinder .

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

Ball Mill Introduction. Ball mill is the most widely used kind of grinding equipment. Zenith Ball mills are widely used in various types of ores'' benefication ...

Ball mill working principle, How Ball Mill work? What is ball . Ball mill application, Ball mill working principle New generation of mills

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

The face milling process can in principle produce very flat surfaces. However, in practice the result always shows visible trochoidal marks following the motion of ...

WhatsApp)

WhatsApp)