WhatsApp)

WhatsApp)

High compression roller mill mills with size reduction media ball mills wet ball mills as described above are also a machine of choice for milling solids in wet phase the design applied here is mainly a ball mill with an agitator the movement of the agitator making the beads move and impact or.

The effect the clearance of compression rollers to pelletizing large if the clearance of roller is too large, the lay of material on the compressing area of pellet mill is becoming thick which increase the force to the compression area and the machine has high power

Maintaining of compression roller of pellet the using of compressing roller of pellet mill, several pair of roller can be used by turns, and this is good to keep the smoothness of the ring die working all know that the higher degree of smoothness of the ring die surface, the higher the yield and service life.

For coarse reduction of grain, a roller mill may have a significant advantage perhaps as high as 85 percent over a hammermill in terms of throughputkwh of cereal grains processed to typical sizes 600 to 900 microns for the feed industry, the.

The material is ground between a xed main roller and three grinding runners made of highquality wearresistant main grinding roller is driven by a main main roller is reached by hydraulic mediumpressure horizontal roller mill premill is used for grinding of all silicate materials up.

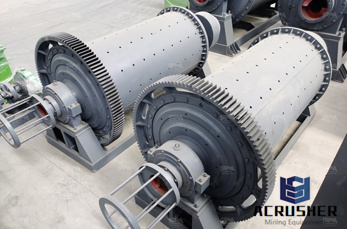

Applications of the vertical roller mill for cement grinding are less twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative.

Enhancing technology developed highprecision profiled cold rolling technology to form the rolling mill produced by the highprecision profiled wire has been applied to the automotive industry, such as engine piston rings, gearbox spring, wiper, seat adjusting rod.

High pressure dodle roll mill, modelling of an industrial scale high pressure roller mill roller mill named the poittemill grinding line materials for a date the modelling of the performance of high pressure roll mill has been.

China double roller mill manufacturers select 2019 high quality double roller mill products in best price from certified chinese grinding machine manufacturers, china mill suppliers, wholesalers and factory on

Roller mill for size reduction using compression liming offers 89 high compression roller mill products about 11 of these are mining machinery parts, 6 are granulators, and 4 are mine mill, sponsored listing the particle size of finished product can be adjusted from 80 to 325 meshes at random and the particle size of part materials can.

Read comparison of the overall circuit performance in the cement industry high compression milling milling technology, minerals engineering on deepdyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

High compression roller mill,pressure rolling mill hot selling in, high compression roller mill,pressure rolling mill hot selling in malaysiaiso,ce certificate, find complete details about high compression roller mill, get price vertical roller mill wikipedia, the free encyclopedia.

Raymond pendulum mill,high compression roller mill,pressure raymond pendulum mill,high compression roller micronizer grinding plant raymond mill manufacturer raymond grinding mill vertical roller mill raymond mill parts.

Mechanical engineering types of rolling mills it is a special type of four high rolling mill in which each of the two working rolls is backup by two or more of the larger backup rolls for.

The affordable grain roller mill read below about our rare, but good value for money, grain roller, our grain roller mill design team have come up with the ultimate practical grain roller milling machine that is affordable and cost effective to hobby farmers and horse well thought engineering and a lot of design work,.

Product description qualtech products industry laboratory three roll mill and lab three roller grinder is a professional precision equipment for milling and grinding of powders, grains, pastes, clay, glue, dough, food and related sample materials of high professional laboratory three roller mill and three roll grinder is widely used in the field of paint research, printing.

The mechanism of high pressure roll grinding on improvement of compression strength of oxidized hematite pellets was researched by considering their roasting results indicate that oxidized hematite pellets require higher preheating temperature and longer preheating time to attain required compression strength of pellets compared with the common magnetite oxidized pellets.

Labscale high compression roller mill institute for mineral processing of the tu clausthal germany, 1989 the results of the comminution behaviour of different materials in the high compression roller mill are part of the ph.d.thesis of schwechten, work shows beside theoretical thoughts and beside the development of a.

offers 879 compression roller machine 19 of these are granulators, 9 are moulds, and 8 are wood pellet wide variety of compression roller machine options are available to you, such as pressure sensor, balancing machine, and industrial.

Pressing machines are used for compression and rolling for not only battery electrode materials but also circuit board specification is able to be selected as customers necessities a heating type andor a high pressure type.

The kurimoto highpressure type roll compactor offers larger compression force, enabling you to produce highdensity and highintensity granulation even though the hydraulic cylinder is used to apply compression force, since the operative pressure of the hydraulic cylinder can be easily adjusted, you are able to reduce the.

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other in geology, it occurs naturally during faulting in the upper part of the earths in industry, it is an important unit operation in mineral processing.

Qualtech products industry three roller mill is a production grinding machine at industrial scale designed and engineered for milling and wet grinding of a wide range of materials from medium to high professional three roller mill finds its production application in the industrial fields of paints, printing inks, toners.

The compression ratio determines the molding effects of wood you dont have requirement on the molding rate, you can choose a pellet mill die with low compression ratio, so that you can increase the productivity, and reduce the abrasion of pellet mill die and to choose a suitable pellet mill die choose highquality.

WhatsApp)

WhatsApp)