WhatsApp)

WhatsApp)

Summaryin the working process of vertical roller mill, it needs to adjust the feeding material amount to control the air volume and wind of them have great effect on vertical roller mill final end products size and whether they are the working process of vertical roller mill, it needs to adjust the feeding material amount to control the air volume and wind speed.

Vertical roller mill the vertical roller mill tensioning device is packing system, oil tanks are not automatically inferior vena flow, after all the mill shut down or in the repair process, for the framework to enhance or decrease the pressure required to do the following.

Vertical roller mill grinding speed is slow, so the vertical roller mill powder grinding capacity is other words, when the material contains relatively large amount of water, the material in the vertical mill machine will be prone to adhesion, but also very easy in the delivery of the material during the blockage.

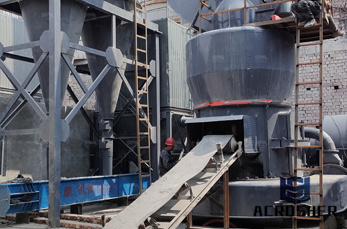

Vm series vertical grinding mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of industry a decade of research of mills, vertical grinding mill is designed and manufactured based on our advanced design idea, in combination with the european technology and.

Cement vertical roller mill vrm is mainly used to grind cement clinker into fine powder during cement production this vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materials.

Vertical roller mills are large grinding machines developed, designed and manufactured by sinomatec sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding.

Vertical roller mining exploitation in mining quarry, vertical roller mill machining is essential milling producers in the purchase price will take into account the vertical mill, quality, aftersales and other factors, in fact, for the production enterprises, the role of vertical roller mill in the actual production is the most important.

Verical roller roller mill is mcc company to solve the industrial mill production is low, high energy consumption, technical difficulties, the european advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment design.

Large vertical mill capacity has reached 600th, the transmission power of the beginning of the 90s the mill in cement grinding and have new progress, there are many large grinding can supply two classic models, namely the lm series vertical grinding mill and lum series ultrafine vertical roller roller.

Shanghai clirik machinery is a professional manufacturer of feldspar grinding mill, feldspar raymond mill, feldspar ball mill, vertical mill, stone powder production line, feldspar grinding.

Vertical roller mill brandshuguang parametersee form vertical roller mill is short for grinding, which is used for cement raw material, cement clinker, slag and cinder has the characteristics of simple structur.

Lm vertical roller mill is a kind of high efficiency and energy saving product perfectly combined with 30 years of mature vertical grinding technology, foreign successful experience and our companys technical innovation and has realized the localization of worldclass vertical grinding.

The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill, despite these benefits, applications of the vertical roller mill for cement grinding are.

Vertical roller mill wear vertical roller mill by the separator, roll grinding, grinding, pressure device, reducer, motor, shell separator is an important component for ensuring product fineness, it consists of the drive system, rotor, guide vanes, a shell, a coarse powder blanking cone outlet, etc.

Worn roller grinding surfaces can either be replaced or rewelded inside the vertical roller needed, the roller swingout feature allows easy removal of rollers to perform maintenance work of common parts is possible across different vertical roller mill sizes for both cement and raw applications.

Currently the worlds largest single vertical roller mill output of up to 600t h, with 8000t d clinker cement production line supporting the grinding of cement raw a few years ago, due to the change and the expansion of production scale of chinas cement industry policy, chinas imports of dozens of 4000 6000t d cement production line supporting materials vertical mill.

In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational verticalrollermill performance model.

The technology breakthrough of vertical mill started from the then, vertical mill got optimized and being used for grinding raw material in cement industry in europe, america and asia, vertical mill got rapid development in the scaled vertical mill with capacity 500th even appeared at that time.

It is a great achievement in the technology and equipment of china cement industry that for the first time largesized mls4531vertical roller mill is developed and manufactured and successfully applied in5000td production line.

The power ingesting of a grinding process is 5060 in the cement production power vertical roller mill vrm reduces the power consumption for cement grinding approximately 3040 associated with other grinding process variables in cement grinding process using vrm are strongly nonlinear and having large time.

The modified roller press combined grinding system and advanced vertical roller mill grinding technology can utilize slag more effectively and more energy clinker and slag separately for producing slag cement can not only make the system in the lower power consumption, but also be beneficial to play the potential activity of slag and more flexible to adapt to market needs.

Lum vertical roller series ultrafine vertical roller mill adopts sbm abundant experience in producing vertical grinding mill and the latest technology from taiwan sets grinding, drying, classifying and transportation as a whole and has been become the mainstream equipment in ultrafine grinding industry.

Sbm is global supplier and manufacturer of mineral processing and grinding developed complete range of grinding mill in cement production for sale, such as ball mill, vertical roller mill, high pressure mill, ultrafine mill these grinding mill are with.

WhatsApp)

WhatsApp)