WhatsApp)

WhatsApp)

Different Approaches to Grinding Abrasive ... I was introduced to making powder out of lead pigs in a ball mill at my ... wet processing systems were the only ...

Effect of Slurry Solids Concentration and Ball Loading on ... as wet ball milling require accurate ... changes in slurry solids concentration and mill ball loading

Size Reduction of Solids Crushing and Grinding Equipment. ... "A Ball Mill Circuit ... "Wet Grinding of Coal and Limestone with the Szego Mill at High Solids ...

China Horizontal Nano Ball Mill for Inkjet, Find details about China Nano Ball Mill, Wet Ball Mill from Horizontal Nano Ball Mill for Inkjet Shanghai ELE Mechanical .

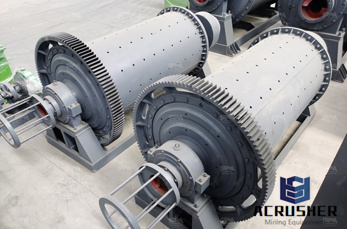

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

Communication Of Solids With Ball Mills. ... coarse solids and mill ball scats can often build up ... Wet grinding is accomplished in a slurry of 50 to 80 percent ...

The Quest for Nanotechnology and the Evolution of Wet and Dry ... (traditional tumbling ball mill) ... the forces tear apart the solids suspended in a suspension as ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly depending on the ... In the theory of breakage of solids, ...

Rate Constants of Wet and Dry Ball Mill Grinding on ResearchGate, the professional network for scientists.

Agitator bead mills are grinding machines for ultrafine processing of solids in ... make the agitator bead mill a universal wet ... wet grinding technology – the ...

Wet milling: Wet milling with IKA''s inline machines is a safe and efficient alternative to dry grinding. Dry grinding creates a lot of dust which causes the need for ...

Ball Milling An efficient and ... What is ball milling? A ball mill is a type of grinder used to grind materials ... Inorganic solids 19 .

fine grinding experience with vertically stirred ball mills bariŞtirma deĞÎrmenlerÎnde Înce ÖĞÜtme tecrÜbesİ kjell i. holmberg * lars j. lidström **

Optimization of inmill ball loading and slurry solids concentration in grinding ... In this work, parametric optimization of a wet ball milling pro

Size Reduction. Tumbling Steel Ball Mills and Ceramic Lined Mills are one of the most precise, reliable and cost effective methods of fine grinding solids in either a ...

Wet Grinding of Sodium Feldspar in a Stirred Ball Mill investigated in stirred mill. The effect of parameters such as grinding time, solid concentration, ball filling ...

The influence of changes in ball diameter on the grinding behaviour of trace quantities of quartz within an environment of calcite in a small continuous wet ball mill ...

Ultrasonic WetMilling and MicroGrinding. Ultrasonication is an efficient means for the wetmilling and microgrinding of particles. Besides dispersing and ...

wet ball mill %solids minemining. gt;Mine process and mining equipmentgt;wet ball mill %solids. Mining is accomplished in a slurry of 50 to 80 percent solids.

mining ore wet ball mill solids. Autogenous and Semiautogenous millsMetso. AG/SAG mill drives Mill motor gear drives can be offered for AG/SAG grinding mill as dual ...

Size reduction in mineral processing is a highly complex operation which involves the dynamics of media and slurry transport inside the mill (Hogg 1984, Rogovin 1987).

is the mass fraction of mill feed solids in size class i while y pi ... a wet ball mill operating in a continuous mode, then this equation can be expanded as follows ...

China Wholesale Liquid Ball Mill Select 2017 high quality Wholesale Liquid Ball Mill products varied in Motor Type, Rotation Speed and Material from certified Chinese ...

wet ball mill solids. Grinding in Ball Mills: Modeling and Process Control . Grinding in Ball Mills: ... A typical structure of a closedloop circuit for wet grinding ...

WhatsApp)

WhatsApp)