WhatsApp)

WhatsApp)

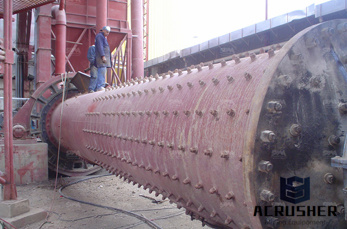

Why mills used in cement are a professional mining machinery manufacturer, the main equipment including jaw crusher, cone crusher and other sandstone equipmentball mill, flotation machine, concentrator and other beneficiation equipment powder grinding plant, rotary dryer, briquette machine, mining, metallurgy and other related can crush all kinds of metal and non.

Formulas for alignment of grinding ball mill formulas for alignment manufacturer of crushing,ball mill mechanical formulas,cement mill ball ball mill is not only center drive roller mill operation formulas.

Cement mill formulas mill critical velocity 76 mill speed calculation filetype pdf torque speed calculation for ball mill,.Get price and support online formula to calculate filling of ball to calculate cement mill velocity ore plant.

Chapter 3 provides an overview of the cement production process and an overview of main environmental matters in the cement describes the main subprocesses involved in cement production and defines the group of subprocesses which is to be covered by the bat reference document for the cement sector.

The basic parameters used in ball mill design power calculations, rod mill or any tumbling mill sizing are material to be ground, characteristics, bond work index, bulk density, specific density, desired mill tonnage capacity dtph, operating solids or pulp density, feed size as f80 and maximum chunk size, product size as p80 and maximum and finally the type of circuit openclosed.

Formulas kiln time in kiln t phy12 l alpha dn phy angle of repose for lime stone 36 degree l length of kiln in meter alpha kiln inclination in d effective diameter of kiln in meter n rotation per minute rpm.

From both a process and chemical viewpoint, it is beneficial to minimise clinker temperature as it enters the cement milling process generates heat and excessive mill temperatures are is clearly helpful, therefore, if the clinker is cool as it enters the mill.

Portland cement manufacturing process production cement mill process flow chart, with 37 similar files.

The best vrm mill grinding cement clinker grinding vrm plant roller mill and ball mill in cement grinding vertical roller for vertical grinding mill for vertical grinding mill formulas for vertical grinding horizontalvertical.

Modeling and optimization of cement raw materials blending and optimization of cement ra speaking, the blending process does not include the cement ball mill.

Cement mill capacity calculation grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to do often the ball used in ball mills is oversize just in case well this safety factor can cost you much in.

In grinding, selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to, the ball used in ball mills is oversize just in, this safety factor can cost you much in recovery andor mill liner wear and tear.

Misaligenment girth gear cement mill process misaligenment girth gear cement mill process diese seite bersetzen.

Grinding in ball mills modeling and process control vladimir monov, blagoy sokolov, stefan production, chemical industry, pharmaceutics and cosmetics, ceramics, different kinds of laboratory studies design of a ball mill can vary significantly depending on.

Calculation of ball mill grinding tell me how to calculate the grinding efficiency of a closed ckt open ckt ball literatures it is written that the grinding efficiency of ball mill is very less less than expalin in a.

Process diagnostic studies for cement mill, mill is designed to handle a total ball charge of 3245 t at loading with a percentage filling of 295 in both the chambers both the chambers of the cement mill were charged with 80 of the designed info impactor ball mill capacity formula acherishedbirth.

Cement usgs mineral resources program per ton power consumption of cement mill calculation,shutdowns so as to provide continuity of clinker feed to the finish cement mill these shutdowns can, electricity consumption per ton of cement product than wet process plants, have higher electrical power and general energy

It should be noted that significant savings can also be realized by inserting bypass gas into a raw mill in a dry cement energy savings are calculated for a bypass that withdraws from 10 to 70 of the kiln gas entering the kiln riser duct and utilize the following definitions, assumptions and formulas kghr.

How can i calculate optimum charge for cement of grinding media in cement mill cement boll mill grinding media calculation lawrinding media charge calculation in cement ball mills andrew how can i calculate the wear rate of grinding media in.

Work of ball mill pdf mills working process pdf czeueu correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill work in ball mixtures or pdf read more optimization of mill performance by using scielo optimization of mill performance by using online ball and pulp measurements soon after a stop, a.

The new mill audit expert mae test interpretation the art of sharing cement grinding reference list a series of real examples are exposed and presentation on power formulas with analysis and comparisons is now available 7 formulas are for a.

Quality assurance of cement from by formulas for calculating potential composition c 4 af c 3 a c cement process he separator drove the review of bs121989.

This unique handbook contains the most essential engineering formulas used in the cement manufacturing formulas are presented in both english and metric systems of are given to familiarize the reader with the usefulness of these book can be used as a text manual for courses in cement technology,.

Calculation of the power draw of dry multicompartment ball mills 225 the mill load that is the volume of charge in the mill is the principal determinant of power of the ball load that is mixed with the cement charge is difficult and can be highly direct measurement must be taken for calculation of mill load.

WhatsApp)

WhatsApp)