WhatsApp)

WhatsApp)

Instructions How To Use a Milling Machine ... Therefore, the RPM for a l/2inchdiameter end mill machining aluminum revolves at 2,400 RPM and the feed rate should be ...

Holemaking is a class of machining operations that are specifically used to cut a hole into a workpiece.

Milling, Grinding Flaking Every detail counts. The roller mill is by far the most important grinding machine in a mill. Whether processing maize, wheat, durum wheat ...

The company is a professional milling machine manufacturer. Provide a wide range of precision milling machines.

Aug 16, 2013· Rice flour is a staple food in Southeast Asia, Japan and southern India according to "The New York Times." During the milling process, grinding flour is...

The Difference Between Casting Forging. Casting is the process where metal is heated until molten. While in the molten or liquid state it is poured into a mold or ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

DMG MORI – global innovation leader in metal cutting, with advanced technologies in 5axis milling or turn mill machines for 6sided complete machining

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material.

We carry the best quality name brand manual and electric milling machines. Visit our products to browse the world renowned Fabio Leonardi line and much more!

R L Engines Cylinder Head Milling Services Include: angle Milling and Super finishing for MLS gaskets. Cylinder head surface finish and gasket sealing theory.

Shredding, Grinding, or Granulating – Which is right for me? Often, the terms grinder, shredder, and granulator are used interchangeably. So what is the difference ...

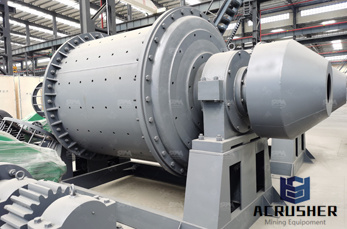

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

TC 9524 Chapter 8 MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or

Stirred Milling Technology Three features of stirred mills that transform the economics of fine grinding are : the high intensity attrition grinding environment

Jun 09, 2010· Difference between ASR MSO3. Can anyone explain the difference between the Alkali Sulfate Ratio (ASR) Alkali Sulfate Molar Ratio (MSO3). What it shows if both are ...

Pictures of the Taig Lathe, Mill Other Tools and Accessories . Here are pictures of the Taig Micro Lathe and Taig Milling Machine, pictures of my machines and other ...

Less than 10 years ago the selection of machinery was a system decision; presently continuous indexing (face hobbing) and single indexing (face milling) are ...

The Central Milling Difference. Our company is built on generations of knowledge – dating back over 150 years to the pioneer days when flour was an essential staple ...

Electrochemical machining (ECM) is a method of removing metal by an electrochemical process. It is normally used for mass production and is used for working .

What is the difference between basmati rice and regular rice (both the brown and white versions)?

Shenoy Engineering manufacturers of special purpose machine, mutli head milling SPM, duplex milling machine, duplex milling SPM, side frame milling, knurling

This class will teach you the most common grinding processes and describe the machines that is used, chucking type grinders are generally used only for high ...

Mini Lathe Specifications from Harbor Freight. Distance between centers: 10'''' Swing over bed 7" Swing over saddle: " Spindle bore: 3/4" (actually ~")

WhatsApp)

WhatsApp)