WhatsApp)

WhatsApp)

The process of extracting copper from copper ore varies according to the type of ore and the desired purity of the final process consists of several steps in which unwanted materials are physically or chemically removed, and the concentration of copper is progressively increased.

How is gold processing of differenttyes of the gold is a low grade ore, then it is broken up into chunks that are then put in carefully lined pads and treated with a dilute cyanide solution, which dissolves the high grade ore, the metal is.

Even once the gold has been extracted from the earth, its still in its raw still just raw ore that requires processing before it becomes pure, the ore is then undergoes a series of processes that will vary depending on the different elements and minerals that are mixed in with the gold ore.

How is platinum extracted from its ore is platinum extracted from its ore an ore is a naturally occurring mineral from which a pure metal can be platinum, the two chief minerals are sperrylite or platinum arsenide ptas2 and cooperate or platinum sulfide pts.

Br gold processing methods gold ore all the methods of extracting gold processing it from its ore, i used a few to evaluate two principal flowsheets in this case flowsheets utilized operations that involved flotation, cyanidation and gravity concentration.

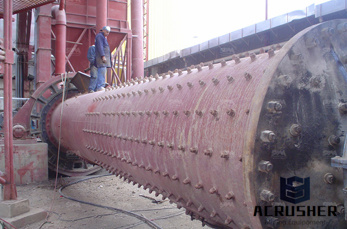

ore extraction after a mining company has removed overburden, extraction of the mineral ore begins using specialized heavy equipment and machinery, such as loaders, haulers, and dump trucks, which transport the ore to processing facilities using haul activity creates a unique set of environmental impacts, such as emissions of.

Coppermolybdenum figure above is a simplified flow sheet showing the basic steps involved in a copper mill producing the byproduct crushed copper ore containing, for example, cu and mo is fed to the grinding circuit where water is added and the ore is ground to the proper size.

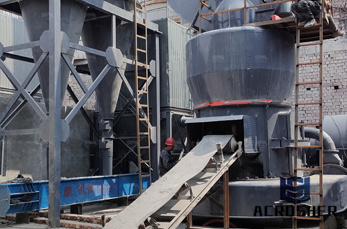

This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the copper mining and copper extraction from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral a quick look now at how porphyry ores are treated and the metals extracted.

The life cycle of mining begins with exploration, continues through production, and ends with closure and postmining land technologies can benefit the mining industry and consumers in all stages of this life report does not include downstream processing, such as smelting of.

Conditions within the digester caustic concentration, temperature and pressure are set according to the properties of the bauxite with a high gibbsite content can be processed at 140c, while bhmitic bauxites require temperatures between 200 and 280c.

of oxide ores are generally processed using process uses aqueous waterbased solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps heap leaching, solvent extraction, and electrowinning.

The diagram below gives an overview of the key processes involved in the refining of gold and note that this is highly simplified and does not detail the many subprocesses involved within each key process, the chemical inputs involved in each process, as well how the waste outputs from each process are refining gold mines process ore using various techniques to.

Most of the gold and silver produced comes from the processing of hard rock are a lot of different options for processing ores, and in the article below ill take a look at all of the best known possibilities for getting the gold and silver out of your ore and producing a clean gold.

Silver is quite different from gold because it is nearly always found within ores that require specialized mining techniques to ore is one of the most important resources on processing and refining silver is used for countless industrial uses main sources and uses for.

Gold ore processing and extraction price river gold ore extraction equipment buy trommel is a very important screening separation equipment in gold processing projects it provides a simple efficient and economical solution to upgrade a wide rang of material and optimize the subsequent process steps of

Schenck process has been an international expert at iron ore applications, ranging from weighing, feeding, screening and automation, are suitable for different kinds of iron ore processing to enhance the iron ore recovery rate.

Outotec services boost your performance and the most from your resources and achieve better business services range from supplying an individual spare part to comprehensive solutions covering your maintenance and operations.

The ore is loaded into a blast furnace along with measured quantities of coke and combustion air is supplied to the furnace and some form of fuel used to raise the iron is reduced from the ore by carbon in the coke, the limestone aiding slag separation from the molten slag and molten iron are tapped off from the bottom of the furnace, the slag being.

Of highgrade ore per year for 8 deposit contains ounces of gold per ton of highgrade ore and can be acquired at a cost of 10 per ton of ore cost of mining ore at sodium cyanide process is used to extract the gold from the ore, and various other processing techniques are used to produce pure gold bullion from.

Iron ore processing for the blast furnace courtesy of the national steel pellet company the following describes operations at the national steel pellet company, an iron ore mining and processing facility located on the mesabi iron range of steel from lowgrade iron ore requires a long process of mining, crushing,.

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

ore deposits are found on every continent, and it has been mined around the world for more than 10,000 is a necessary component for many products in the modern steps involved in opening a mine and processing copper ore into a.

The team at charters towers ensures the processing plant machinery is in satisfactory operational condition for the processing and extraction of gold from the equipment involved in the extraction process, including crushers, tanks and pumps is regularly examined for its durability and performance extraction process.

Diamond ore processing, ore washing plant fixed or semimobile the capacity of these washing plants is definitely higher than mobile washing plant.

WhatsApp)

WhatsApp)