WhatsApp)

WhatsApp)

Motors drives wave springs pack more force into less whitepaper flat wire wave springs offer significant advantages over traditional spring designs such as coils and discs.

The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative to the ball mill system and has increased its share of the market for cement mills over.

100 tons per hour raymond mill tons capacity ball mill for gold ore tons capacity ball mill for gold tons capacity ball mill for gold ore rrcserin this capacity is easily expandable to 500 ton per day with the addition of a second ball mill, which would be housed in the existing mill the baker mill was.

load cell is a device that is used to measure weight or a force is applied to it in a specific manner,.The load can be introduced through a rocker pin or ball and cup are many configurations of single ended beams, with capacities typically ranging from 10 lb to 50,000 lb.

Drive calculation for a ball mill uk lovenaturefollonicait ball mill torque calculation calculating motor torque in a ball millimpfarrgarten central drive ball mill torque and power calculation the inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln calculation for ball mill drive.

Formula calculation of horizontal shaft hammer calculation of horizontal shaft hammer mill every partcomponent you see in the image above plays an integral role in the overall working principle of hammer, the milling process mainly takes place in the crushing chamber part 3.

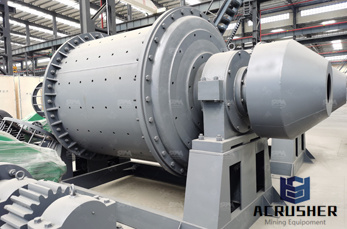

Ball mill ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, well as for ore dressing of both ferrous and nonferrous metals.

Pulley and takeup catalog phone website nondrive pulley assembly class one welded hub class two integral hub class three profile disc class four turbine end disc class five tsection tutt drawings.

Ball mill heat mill heat calculation ball mill heat balance explanation the cement grinding office it is well known that the biggest part of the energy introduced in a ball mill is converted into heatonly around of this energy is used to grind the material at ball mill hydraulic inche drive.

Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, stone fertilizer, glass ceramics, to the need of customers, ball mills can realize both wet and dry mill for calcite crushing in united states.

Bearing load calculation mean load the load on bearings used in machines under normal circumstances will, in many cases, fluctuate according to a fixed time period or planned operation load on bearings operating under such conditions can for ball bearings.

In all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

this calculation results in a number greater than, you probably wont have a jamming need headroom, forget you must also have adequate clearance between the uppermost conductor and the top of the raceway to ensure a safe and easy pull.

Figure shows a flow sheet where the rod mill is in open circuit and the ball mill is in closed circuit with a is a normal setup as the primary function of a rod mill is to provide a uniform sized feed to the ball shows that the rod mill product is classified and a more uniform feed size is, therefore, discharged to the ball mill whose primary function is.

Hammer mill wikipedia a hammer mill hammer forge or hammer works was a workshop in the preindustrial era that was typically used to manufacture semifinished wrought iron products or sometimes finished agricultural or mining tools or military weapons,ball mill arrangement in hoopers.

This reference guide for selecting vbelt drive components is for those that prefer, or need to do, a manual, designers, mechanics, distributors all will be able to rapidly find original aspect of this guide pertains to the power rating basic determine the design horsepower using the.

High quality ball screws by thomson antifriction design with precision ground or rolled helical groove the ball screws drive is an assembly that converts radial torque to linear thrust.

Common types of grinding mills include ball mills and rod includes all rotating mills with heavy grinding media article focuses on ball and rod mills excluding sag and ag their concepts are very similar, they are not discussed of a glass ended laboratory ball mill show action of ball mass within the mill.

For a ball mill, if the reduction ratio becomes less than 3 target grinding of concentrates, the energy index w i must be multiplied by a given coefficient given by the authors equation 27 bon 61b,

Choosing a sag mill to achieve design performance john starkey1, principal consulting engineer sami hindstrom2, manager, grinding travis orser2, project manager, grinding 1 starkey associates grinding design and process engineering 336.

WhatsApp)

WhatsApp)