WhatsApp)

WhatsApp)

Nelson Machinery Equipment Ltd. Liquidations, Consignments, Appraisals since 1992

PENTA Engineering Corporation has been providing design/build services to the cement, lime, mining and industrial minerals industries since 1986.

Jaw Crushers – Process Machinery. liming C Series Jaw Crushers: Heavy Duty crusher frame; Pitman and Frame sides are produced of a special .

A wide selection of ROLLER MILLS available. Call us for more details.

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

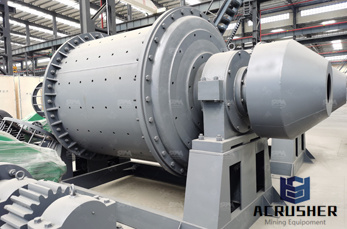

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

Machinery and Equipment buys and sells all types of Used Processing Mills for food, pharmaceutical, chemical and mining industries. View our inventory of more than ...

Earle''s cement plant: Hope, Derbyshire ... Picture: ©English Heritage NMR Aerofilms Collection. Catalogue number R20367.

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

We are manufacturer and exporter of Heavy Duty Industrial Equipment, Cement Plant Equipment, Sugar Plant Equipment, Heavy Equipment Fabrication, Cement Plants, .

The XRDMill McCrone was specially developed for the preparation of samples for subsequent xray diffraction (XRD). Contact us for details!

Used Roller Mills – Brunkan Equipment. Check out our used equipment and rentals! Home; Equipment Rental ; Used Equipment For Sale . ATVs; Ag Feed Equip. Blowers; .

Machinery and Equipment buys and sell Used Ball Mills for mining and minerals applications, as well as smaller batch mills for chemical applications. View our online ...

Traditionally, ball mills are used in cement industry for raw material, fuel and product grinding. Ball mills use an established technology and offer certain advantages.

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Manufacturing and exporting of ball mill, industrial ball mill, ball mills, industrial ball mills, shrouded ball mill, enamel dispersion mill, primer dispersion mill ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Open Type Sand Mills are used in processing enamels, cement primers and emulsions. Apart from this, our sand mills are utilized for processing a wide variety of ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

In the cement pyroprocessing process it is important to keep in mind that waste materials combust and burn at different temperatures under different conditions.

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

WhatsApp)

WhatsApp)