WhatsApp)

WhatsApp)

The cement industry accounts for approximately 5 percent of current anthropogenic carbon dioxide (CO 2)emissions worldwide. World cement demand and production .

Homepage > Activities > Cement > Production cycle > Production cycle. Step 3: The "cooking" process. ... (precalcination phase).

Dry Kilns with Multistage Preheaters and Precalcination. Vertical preheater|Vertical preheaters. ... Low SO2 Emission Preheaters for Cement Production DTU Orbit.

Numerical modelling of calcination reaction ... Numerical modelling of calcination reaction mechanism for cement production ...

CFD Modelling of Alumina Calciner Furnaces ... regions responsible for NOx production. NOMENCLATURE A Preexponential factor ... the cement, alumina and ...

Dry Kilns with Multistage Preheaters and Precalcination; ... only 45% of the Chinese cement production capacity was ... Dry Kilns with Multistage Preheaters ...

The Reduced Emission Oxygen Kiln ... The REO kiln represents a paradigm shift in cement production that aims to capture ... 3 Calcination Reaction in N

Numerical modelling of flow and transport processes in a calciner for cement production ... Controlling the calcination process in industrial cement kilns is of ...

General description of the reactions in the cement ... without a precalciner, most of the calcination takes place in ... a complex process like cement production.

the calcining in cement plant pdf . ... co2 emissions from cement production ... Dry Kilns with Multistage Preheaters and Precalcination ...

Mikulčić, Hrvoje and Vujanović, Milan and Duić, Neven (2011) Reducing the CO2 emissions in Croatia''s cement industry – the precalciner model. = Reducing the ...

Cement production is rather decen ... and some calcination occur in the preheater, calcination is largely completed in the precalciner, and the kiln is used

The REO kiln represents a paradigm shift in cement production that aims to capture virtually all ... The Reduced Emission Oxygen Kiln ... 3 Calcination Reaction in N

Cement production line introduction: ... Mainly by crushing and prehomogenization, ... The raw meal homogenization is a key factor for stable clinker calcination. 4.

Oct 07, 2008· Percent Calcination. I came upon this Erratum on the PCA web site: Two formulas are shown to calculate the ...

In modern cement plants, raw meal is pre ... using kiln string only. • Production down to 20% of capacity for ... • Calcination at kiln inlet: 9095%

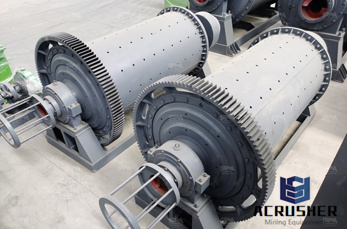

Rotary kiln,ball mill,Vertical Preheater,Granulator,cement kiln ... Magnesium Calcination Production Line. Henan Zhengzhou Mining Machinery Co., Ltd. was ...

On Jan 1, 2005 M. Hillers (and others) published: Process soptimization for a pre calciner facility of the cement industry

cement production Hrvoje Mikulcˇic´ a ... preheats the particle from the ambient temperature to the decomposition temperature. ... Chemical Engineering Science

Addition of PreCalcination to Kilns with Preheaters. Process Control and Optimization in Clinker Making. ... Cement production is an energy intensive process, ...

The first application of preheated kiln was realised by Ishikawajima Harima Heavy Industries in 1971. Precalcination technology has made great progress in a short ...

Percent Calcination So just what is the meaning of the term, ... that unfortunately we''ve incorrectly answered in our Innovations in Portland Cement

... Cement Industry Emissions. On ... of the amount released during cement calcination. ... in concrete production to limit the need for cement ...

Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: ... (up to 1450 °C) in a cement kiln;

WhatsApp)

WhatsApp)